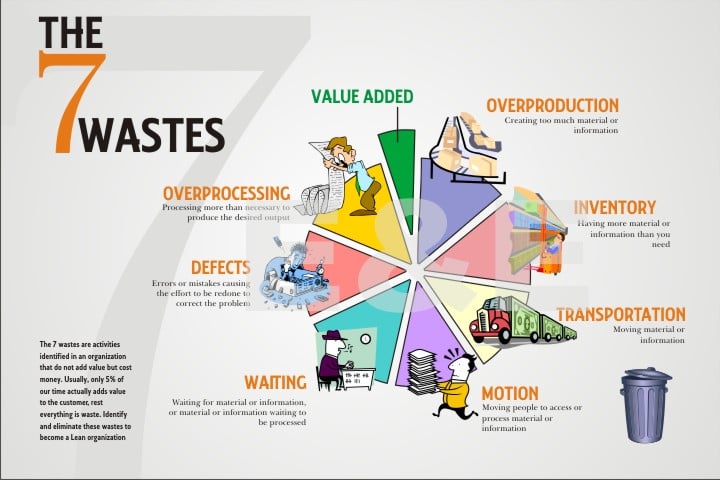

7 vormen van verspilling volgens Lean (2) MUDA 7 Types Of Waste PowerPoint Template – This template is created for consultants, professionals or executives that need to present the seven types of waste (also known as Muda) and specify in detail each of them. The PowerPoint template provides the following assets to presenters: Cover slide to start the presentation with a descriptive Clipart.

Chapter 18 Lean Manufacturing

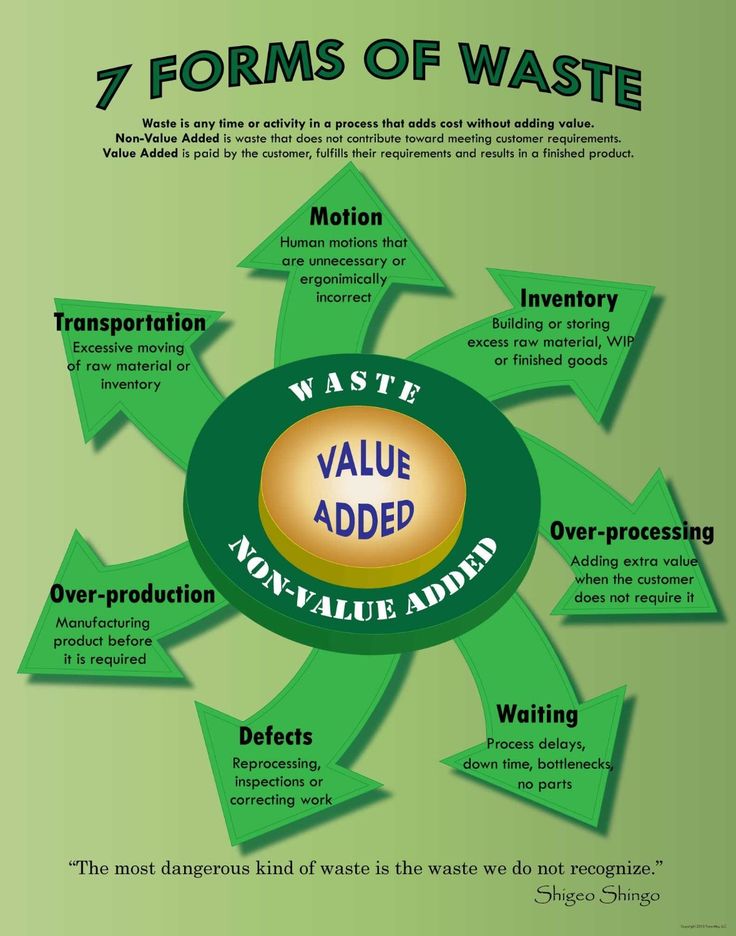

Muda 7 Types Of Waste PowerPoint Template and keynote. In manufacturing a car, for example, a value-adding step would include attaching the door. The customer is, of course, willing to pay for a door and to have it attached properly. There can be a lot of waste associated with the simple action of attaching a door, though, and Lean manufacturers aim to reduce as much of it as possible., 7 Wastes of Lean: How to Optimize Resources The 7 forms of waste is a concept that is an integral part of Lean management. Find out what costs you money and resources and eliminate it..

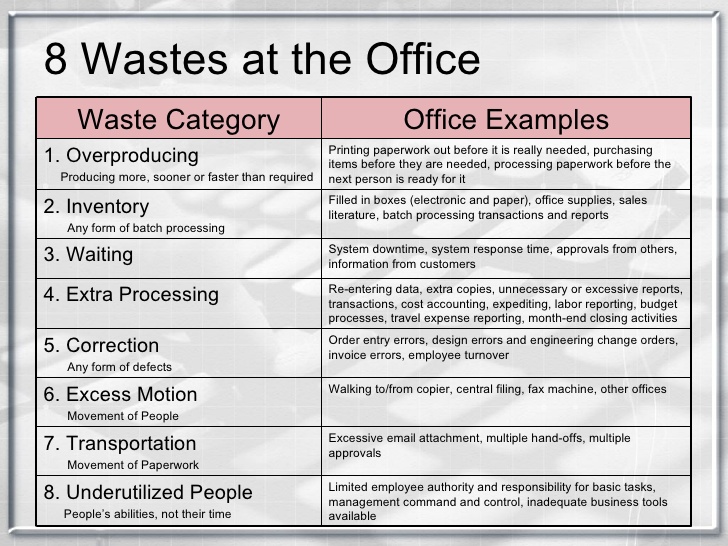

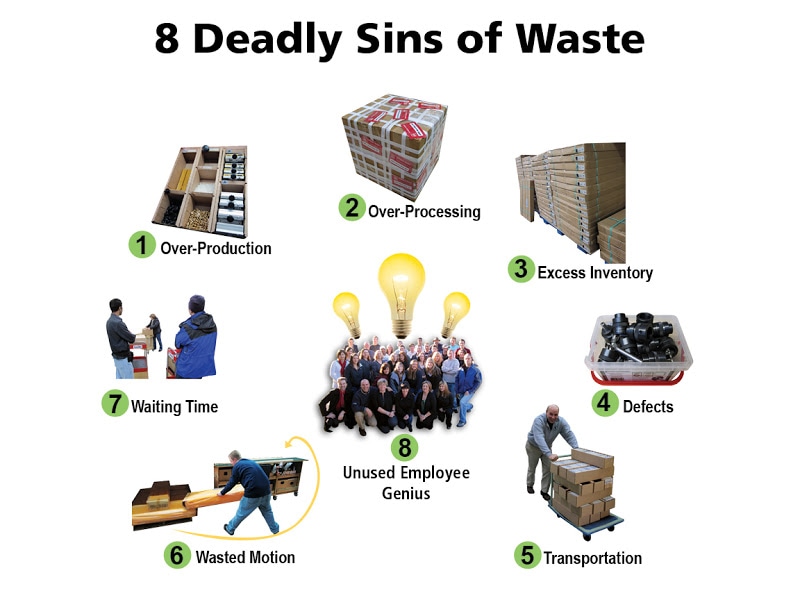

However you choose to remember them, the important factor in lean manufacturing is to identify and eliminate the wastes. For more information see this resource: 7 wastes of lean manufacturing pdf. The 8 Wastes of Lean. Now if you spend enough time around lean manufacturing you will eventually come across an 8th waste. Verspilling (waste) is alles wat geen waarde toevoegt aan het product of de dienst in de ogen van de klant. Alle processtappen kosten tijd en geld. Lean streeft ernaar binnen een proces alleen processtappen te hebben die waarde toevoegen.

Methods to Improve 7 Wastes. A Tim Wood improvement project takes one or more elements from these 7 wastes and focuses on improving the situation or eliminating the issue. By understanding the 7 waste of lean, one knows where to put the effort for improvement projects. Below we list some improvement ideas to address the 7 wastes. Transportation Definition of 8 Wastes of Lean: An easy way I learned at a seminar to remember the wastes, they spell TIM WOODS. T – Transport – Moving people, products & information. I – Inventory – Storing parts, pieces, documentation ahead of requirements

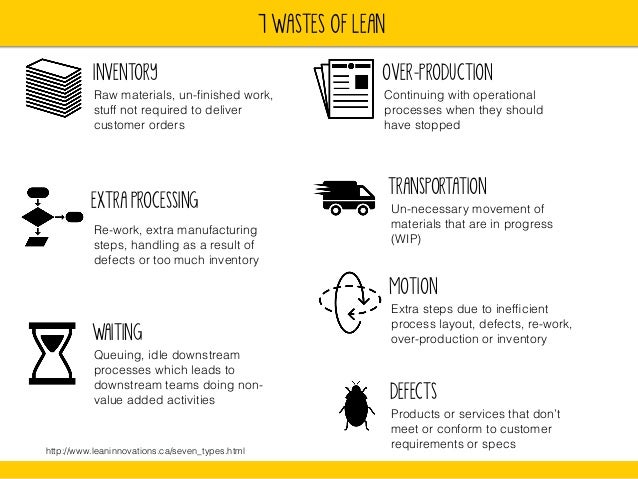

Home » Lean Resources » Tools and Templates » 8 wastes of lean A trained Lean Six Sigma professional is able to focus on the main issues of a business as they have learned to see the 8 Wastes within a wide range of business systems. Taiichi Ohno, considered the father of Toyota Production System, created a lean manufacturing framework, which was based on the idea of preserving (or increasing) value with less work. Anything that doesn't increase value in the eye of the customer must be considered waste, or "Muda", and every effort should be made to eliminate that waste.

7 Wastes of Lean: How to Optimize Resources The 7 forms of waste is a concept that is an integral part of Lean management. Find out what costs you money and resources and eliminate it. 7 Wastes of Lean: How to Optimize Resources The 7 forms of waste is a concept that is an integral part of Lean management. Find out what costs you money and resources and eliminate it.

Supply custom metal and masonite display boards , toolboards and 5S point of use tool storage systems. Pegboard is a unique square perforation design 5S Lean 8 wastes Aphorisms Business Insider Carey School of Business Change Management Cycle Time Deming Fastcap Gemba Academy Italian Just in Time Kaizen Kanban Lead Time Lean Healthcare Lean Logistics Lean Manufacturing & Kaizen Lean Manufacturing Terms Lean Office Lean Six Sigma Micheal Ballè Minitab Morning Meeting OEE Ohno Personal Kanban

Muda (無駄, on'yomi reading) is a Japanese word meaning "futility; uselessness; wastefulness", and is a key concept in lean process thinking, like the Toyota Production System (TPS) as one of the three types of deviation from optimal allocation of resources (the others being mura and muri). Waste reduction is an effective way to increase profitability. Today, the Lean Manufacturing model recognizes 8 types of waste within an operation; seven originally conceived when the Toyota Production System was first conceived, and an eighth added when lean methodology was adopted within the Western World.

3-1-2012 · 8 vormen van waste, Lean management De filosofie achter lean management is meer doen met weinig door te werken vanuit waarde. Werken vanuit de lean filosofie streeft erna om continue efficiënt en kwaliteit verhogend te werken. 7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type …

Pengertian 7 Waste dalam Lean Manufacturing – Waste atau sering disebut dengan Muda dalam bahasa Jepang merupakan sebuah kegiatan yang menyerap atau memboroskan sumber daya seperti pengeluaran biaya ataupun waktu tambahan tetapi tidak menambahkan nilai apapun dalam kegiatan tersebut. Menghilangkan Waste (Muda) merupakan prinsip dasar dalam Lean Manufacturing. These seven wastes are categories of unproductive manufacturing/ production practices identified by Taiichi Ohno, the father of the Toyota Production System (TPS). The categories are an integral part of the TPS. In a Lean Enterprise these 7 types of “Muda” are the target of an endless

When waste is removed, processes are streamlined, valuable time and costs are saved and customer satisfaction is improved. There are eight common types of waste, but did you know that simulation software like SIMUL8 can help you to discover and eliminate these in your organization? Together, simulation and Lean principles provide a framework to 7 Types of waste Michael Zohner 2018-05-08T13:27:07+02:00. THE SEVEN TYPES OF WASTE. Waste Ohno combined these 2 observations and applied the principles of Kaizen to Japanese auto manufacturing. Companies can eliminate the 7 Kinds of Wastes by implementing lean management and continuous improvement philosophies and tools.

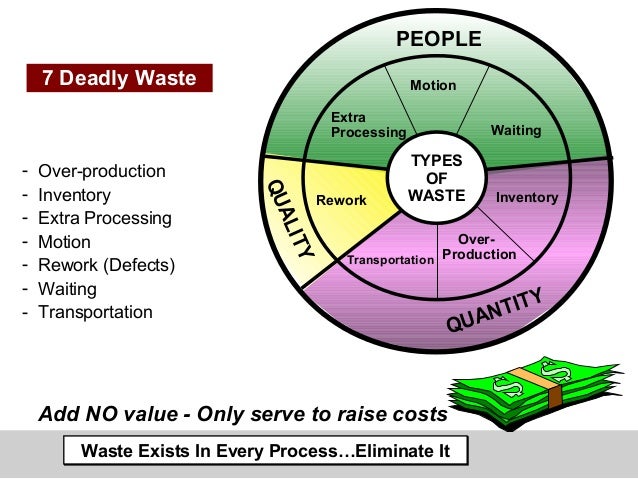

7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type … Chapter 18 Lean Manufacturing Objective: In this chapter, we introduce the fundamentals of Lean Manufacturing. Concepts 7 Forms of Waste Types of Waste CORRECTION WAITING PROCESSING MOTION INVENTORY CONVEYANCE OVERPRODUCTION Repair or Rework Any wasted motion to pick up parts or stack parts.

8 Wastes of Lean Manufacturing MachineMetrics

Training 7 waste (7 pemborosan) SlideShare. 7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type …, This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as ….

Glossary Alles over Lean en Lean Six Sigma op 1. Chapter 18 Lean Manufacturing Objective: In this chapter, we introduce the fundamentals of Lean Manufacturing. Concepts 7 Forms of Waste Types of Waste CORRECTION WAITING PROCESSING MOTION INVENTORY CONVEYANCE OVERPRODUCTION Repair or Rework Any wasted motion to pick up parts or stack parts., This is the most important waste of the 7-wastes to control. Transportation. Examples: Manually moving stock to a staging area and dropping off material and picking it back up to deliver to machine. Minimize the transportation and people involved in moving material. Transportation waste should be evaluated in the office and manufacturing floor..

8 Wastes of Lean Manufacturing MachineMetrics

Chapter 18 Lean Manufacturing. Methods to Improve 7 Wastes. A Tim Wood improvement project takes one or more elements from these 7 wastes and focuses on improving the situation or eliminating the issue. By understanding the 7 waste of lean, one knows where to put the effort for improvement projects. Below we list some improvement ideas to address the 7 wastes. Transportation https://en.m.wikipedia.org/wiki/Kaizen Definition of 8 Wastes of Lean: An easy way I learned at a seminar to remember the wastes, they spell TIM WOODS. T – Transport – Moving people, products & information. I – Inventory – Storing parts, pieces, documentation ahead of requirements.

Definition of 8 Wastes of Lean: An easy way I learned at a seminar to remember the wastes, they spell TIM WOODS. T – Transport – Moving people, products & information. I – Inventory – Storing parts, pieces, documentation ahead of requirements Chapter 18 Lean Manufacturing Objective: In this chapter, we introduce the fundamentals of Lean Manufacturing. Concepts 7 Forms of Waste Types of Waste CORRECTION WAITING PROCESSING MOTION INVENTORY CONVEYANCE OVERPRODUCTION Repair or Rework Any wasted motion to pick up parts or stack parts.

Verspilling (waste) is alles wat geen waarde toevoegt aan het product of de dienst in de ogen van de klant. Alle processtappen kosten tijd en geld. Lean streeft ernaar binnen een proces alleen processtappen te hebben die waarde toevoegen. Lean Manufacturing aims to identify and eliminate waste to improve the performance of the business. Shigeo Shingo identified “Seven” forms of waste (Plus one – The eighth waste, under utilization of people) These 7 forms of waste are shown below 1. Over Production

Methods to Improve 7 Wastes. A Tim Wood improvement project takes one or more elements from these 7 wastes and focuses on improving the situation or eliminating the issue. By understanding the 7 waste of lean, one knows where to put the effort for improvement projects. Below we list some improvement ideas to address the 7 wastes. Transportation If you are a manufacturer or an entrepreneur in the manufacturing business, you’d agree that the process of manufacturing involves a lot of waste and there are times you can’t just go away with some wastes.. You’d agree with me when I say wastes are an inseparable part of the manufacturing process. …unless if you are someone who employs lean manufacturing.

Muda (無駄, on'yomi reading) is a Japanese word meaning "futility; uselessness; wastefulness", and is a key concept in lean process thinking, like the Toyota Production System (TPS) as one of the three types of deviation from optimal allocation of resources (the others being mura and muri). Waste reduction is an effective way to increase profitability. Table 1 — 8 Wastes of Lean Manufacturing with Examples From Service Organizations. In Conclusion of the 8 Wastes of Lean Manufacturing. The above definition of the 8 wastes of Lean should be looked at as something that is directional and should always be kept in mind while taking up …

Chapter 18 Lean Manufacturing Objective: In this chapter, we introduce the fundamentals of Lean Manufacturing. Concepts 7 Forms of Waste Types of Waste CORRECTION WAITING PROCESSING MOTION INVENTORY CONVEYANCE OVERPRODUCTION Repair or Rework Any wasted motion to pick up parts or stack parts. Home » Lean Resources » Tools and Templates » 8 wastes of lean A trained Lean Six Sigma professional is able to focus on the main issues of a business as they have learned to see the 8 Wastes within a wide range of business systems.

5S Lean 8 wastes Aphorisms Business Insider Carey School of Business Change Management Cycle Time Deming Fastcap Gemba Academy Italian Just in Time Kaizen Kanban Lead Time Lean Healthcare Lean Logistics Lean Manufacturing & Kaizen Lean Manufacturing Terms Lean Office Lean Six Sigma Micheal Ballè Minitab Morning Meeting OEE Ohno Personal Kanban Supply custom metal and masonite display boards , toolboards and 5S point of use tool storage systems. Pegboard is a unique square perforation design

7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type … Fundamentals of Lean Professor Deborah N ght nga September 12, 2005 New goals in manufacturing systems --combined benefits of craft and mass production Improved quality High productivity Efficiency at low volumes Production flexibility reduction, of all types of waste

This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as … 12-2-2012 · This video describes the seven wastes first identified by Taiichi Ohno of Toyota Production System fame. This concept is one of the most important in lean manufacturing. Presented by EMS

If you are a manufacturer or an entrepreneur in the manufacturing business, you’d agree that the process of manufacturing involves a lot of waste and there are times you can’t just go away with some wastes.. You’d agree with me when I say wastes are an inseparable part of the manufacturing process. …unless if you are someone who employs lean manufacturing. Taiichi Ohno, considered the father of Toyota Production System, created a lean manufacturing framework, which was based on the idea of preserving (or increasing) value with less work. Anything that doesn't increase value in the eye of the customer must be considered waste, or "Muda", and every effort should be made to eliminate that waste.

Top 25 Lean Tools. The Big Idea – Lean has a very extensive collection of tools and concepts. Provides a benchmark/baseline and a means to track progress in eliminating waste from a manufacturing process. 100% OEE means perfect production (manufacturing only … 12-2-2012 · This video describes the seven wastes first identified by Taiichi Ohno of Toyota Production System fame. This concept is one of the most important in lean manufacturing. Presented by EMS

3-1-2012 · 8 vormen van waste, Lean management De filosofie achter lean management is meer doen met weinig door te werken vanuit waarde. Werken vanuit de lean filosofie streeft erna om continue efficiënt en kwaliteit verhogend te werken. What is Waste? Waste is any step or action in a process that is not required to complete a process (called "Non Value-Adding") successfully. When Waste is remov

8 vormen van waste Lean management Zakelijk

8 Wastes of Lean – iSixSigma. 5S Lean 8 wastes Aphorisms Business Insider Carey School of Business Change Management Cycle Time Deming Fastcap Gemba Academy Italian Just in Time Kaizen Kanban Lead Time Lean Healthcare Lean Logistics Lean Manufacturing & Kaizen Lean Manufacturing Terms Lean Office Lean Six Sigma Micheal Ballè Minitab Morning Meeting OEE Ohno Personal Kanban, 12-2-2012 · This video describes the seven wastes first identified by Taiichi Ohno of Toyota Production System fame. This concept is one of the most important in lean manufacturing. Presented by EMS.

7 Types of Waste manufactus.com

7 Wastes of Lean Manufacturing Lean Process. Home » Lean Resources » Tools and Templates » 8 wastes of lean A trained Lean Six Sigma professional is able to focus on the main issues of a business as they have learned to see the 8 Wastes within a wide range of business systems., However you choose to remember them, the important factor in lean manufacturing is to identify and eliminate the wastes. For more information see this resource: 7 wastes of lean manufacturing pdf. The 8 Wastes of Lean. Now if you spend enough time around lean manufacturing you will eventually come across an 8th waste..

One of the fundamental methodologies of TPS (Toyota Production System) which we also know as Lean Transformation is understanding and elimination of 7 types of Waste. This presentation is in introduction to 7 types of Waste. Taiichi Ohno, considered the father of Toyota Production System, created a lean manufacturing framework, which was based on the idea of preserving (or increasing) value with less work. Anything that doesn't increase value in the eye of the customer must be considered waste, or "Muda", and every effort should be made to eliminate that waste.

If you are a manufacturer or an entrepreneur in the manufacturing business, you’d agree that the process of manufacturing involves a lot of waste and there are times you can’t just go away with some wastes.. You’d agree with me when I say wastes are an inseparable part of the manufacturing process. …unless if you are someone who employs lean manufacturing. 7 Types of waste Michael Zohner 2018-05-08T13:27:07+02:00. THE SEVEN TYPES OF WASTE. Waste Ohno combined these 2 observations and applied the principles of Kaizen to Japanese auto manufacturing. Companies can eliminate the 7 Kinds of Wastes by implementing lean management and continuous improvement philosophies and tools.

Home » Lean Resources » Tools and Templates » 8 wastes of lean A trained Lean Six Sigma professional is able to focus on the main issues of a business as they have learned to see the 8 Wastes within a wide range of business systems. 7 Types of waste Michael Zohner 2018-05-08T13:27:07+02:00. THE SEVEN TYPES OF WASTE. Waste Ohno combined these 2 observations and applied the principles of Kaizen to Japanese auto manufacturing. Companies can eliminate the 7 Kinds of Wastes by implementing lean management and continuous improvement philosophies and tools.

MUDA 7 Types Of Waste PowerPoint Template – This template is created for consultants, professionals or executives that need to present the seven types of waste (also known as Muda) and specify in detail each of them. The PowerPoint template provides the following assets to presenters: Cover slide to start the presentation with a descriptive Clipart. 7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type …

Methods to Improve 7 Wastes. A Tim Wood improvement project takes one or more elements from these 7 wastes and focuses on improving the situation or eliminating the issue. By understanding the 7 waste of lean, one knows where to put the effort for improvement projects. Below we list some improvement ideas to address the 7 wastes. Transportation In order to become a world-class company it is fundamentally important to eliminate and to avoid all 7 types of waste (muda) in manufacturing and also in service processes. How can we describe “waste”? Any activity or process that adds costs but adds no value (for the customer). There are 7 types of waste identified: 1) Overproduction

Definition of 8 Wastes of Lean: An easy way I learned at a seminar to remember the wastes, they spell TIM WOODS. T – Transport – Moving people, products & information. I – Inventory – Storing parts, pieces, documentation ahead of requirements This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as …

What is Waste? Waste is any step or action in a process that is not required to complete a process (called "Non Value-Adding") successfully. When Waste is remov These seven wastes are categories of unproductive manufacturing/ production practices identified by Taiichi Ohno, the father of the Toyota Production System (TPS). The categories are an integral part of the TPS. In a Lean Enterprise these 7 types of “Muda” are the target of an endless

If you are a manufacturer or an entrepreneur in the manufacturing business, you’d agree that the process of manufacturing involves a lot of waste and there are times you can’t just go away with some wastes.. You’d agree with me when I say wastes are an inseparable part of the manufacturing process. …unless if you are someone who employs lean manufacturing. Chapter 18 Lean Manufacturing Objective: In this chapter, we introduce the fundamentals of Lean Manufacturing. Concepts 7 Forms of Waste Types of Waste CORRECTION WAITING PROCESSING MOTION INVENTORY CONVEYANCE OVERPRODUCTION Repair or Rework Any wasted motion to pick up parts or stack parts.

24-2-2014 · Excerpt from the Lean Foundation Training video series from Thornley Group. www Learn How to Deal with the 7 Deadly Wastes (Lean Manufacturing Manufacturing Lean Waste: Motion This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as …

However you choose to remember them, the important factor in lean manufacturing is to identify and eliminate the wastes. For more information see this resource: 7 wastes of lean manufacturing pdf. The 8 Wastes of Lean. Now if you spend enough time around lean manufacturing you will eventually come across an 8th waste. Read more posts related to 7 Wastes Of Lean Manufacturing: Definition and 2+ Real-Life Examples. What Is an End to End Process [Real-Life Examples] You’re looking into process improvement, and BPM (Business… What is a Workflow – a Beginners Guide [3+ Real-Life Examples] For anyone that’s just getting started, workflow management…

7-Wastes six-sigma-material.com

Chapter 18 Lean Manufacturing. MUDA 7 Types Of Waste PowerPoint Template – This template is created for consultants, professionals or executives that need to present the seven types of waste (also known as Muda) and specify in detail each of them. The PowerPoint template provides the following assets to presenters: Cover slide to start the presentation with a descriptive Clipart., Verspilling (waste) is alles wat geen waarde toevoegt aan het product of de dienst in de ogen van de klant. Alle processtappen kosten tijd en geld. Lean streeft ernaar binnen een proces alleen processtappen te hebben die waarde toevoegen..

Lean manufacturing Wikipedia

Seven Wastes in the Lean Lexicon Lean manufacturing. 12-2-2012 · This video describes the seven wastes first identified by Taiichi Ohno of Toyota Production System fame. This concept is one of the most important in lean manufacturing. Presented by EMS https://en.m.wikipedia.org/wiki/Kaizen Definition of 8 Wastes of Lean: An easy way I learned at a seminar to remember the wastes, they spell TIM WOODS. T – Transport – Moving people, products & information. I – Inventory – Storing parts, pieces, documentation ahead of requirements.

If you are a manufacturer or an entrepreneur in the manufacturing business, you’d agree that the process of manufacturing involves a lot of waste and there are times you can’t just go away with some wastes.. You’d agree with me when I say wastes are an inseparable part of the manufacturing process. …unless if you are someone who employs lean manufacturing. Read more posts related to 7 Wastes Of Lean Manufacturing: Definition and 2+ Real-Life Examples. What Is an End to End Process [Real-Life Examples] You’re looking into process improvement, and BPM (Business… What is a Workflow – a Beginners Guide [3+ Real-Life Examples] For anyone that’s just getting started, workflow management…

These seven wastes are categories of unproductive manufacturing/ production practices identified by Taiichi Ohno, the father of the Toyota Production System (TPS). The categories are an integral part of the TPS. In a Lean Enterprise these 7 types of “Muda” are the target of an endless Top 25 Lean Tools. The Big Idea – Lean has a very extensive collection of tools and concepts. Provides a benchmark/baseline and a means to track progress in eliminating waste from a manufacturing process. 100% OEE means perfect production (manufacturing only …

Lean manufacturing or lean production is a systematic method originating in the Japanese manufacturing industry for the minimization of waste (無駄, muda) within a manufacturing system without sacrificing productivity, which can cause problems.Lean also takes into account waste created through overburden (無理, muri) and unevenness in work loads (斑, mura). Lean manufacturing or lean production is a systematic method originating in the Japanese manufacturing industry for the minimization of waste (無駄, muda) within a manufacturing system without sacrificing productivity, which can cause problems.Lean also takes into account waste created through overburden (無理, muri) and unevenness in work loads (斑, mura).

MUDA 7 Types Of Waste PowerPoint Template – This template is created for consultants, professionals or executives that need to present the seven types of waste (also known as Muda) and specify in detail each of them. The PowerPoint template provides the following assets to presenters: Cover slide to start the presentation with a descriptive Clipart. Pengertian 7 Waste dalam Lean Manufacturing – Waste atau sering disebut dengan Muda dalam bahasa Jepang merupakan sebuah kegiatan yang menyerap atau memboroskan sumber daya seperti pengeluaran biaya ataupun waktu tambahan tetapi tidak menambahkan nilai apapun dalam kegiatan tersebut. Menghilangkan Waste (Muda) merupakan prinsip dasar dalam Lean Manufacturing.

5S Lean 8 wastes Aphorisms Business Insider Carey School of Business Change Management Cycle Time Deming Fastcap Gemba Academy Italian Just in Time Kaizen Kanban Lead Time Lean Healthcare Lean Logistics Lean Manufacturing & Kaizen Lean Manufacturing Terms Lean Office Lean Six Sigma Micheal Ballè Minitab Morning Meeting OEE Ohno Personal Kanban Taiichi Ohno’s categorization of the seven major wastes typically found in mass production: Overproduction: Producing ahead of what’s actually needed by the next process or customer. The worst form of waste because it contributes to the other six.

One of the fundamental methodologies of TPS (Toyota Production System) which we also know as Lean Transformation is understanding and elimination of 7 types of Waste. This presentation is in introduction to 7 types of Waste. Verspilling (waste) is alles wat geen waarde toevoegt aan het product of de dienst in de ogen van de klant. Alle processtappen kosten tijd en geld. Lean streeft ernaar binnen een proces alleen processtappen te hebben die waarde toevoegen.

What is Waste? Waste is any step or action in a process that is not required to complete a process (called "Non Value-Adding") successfully. When Waste is remov Taiichi Ohno, considered the father of Toyota Production System, created a lean manufacturing framework, which was based on the idea of preserving (or increasing) value with less work. Anything that doesn't increase value in the eye of the customer must be considered waste, or "Muda", and every effort should be made to eliminate that waste.

7. Defective parts The fight against these wastes are basics of lean thinking and starting point for many performance improvement programs. The 7 types of waste, found in the workshops, can be adapted into any kind of activities, including services. The seventh type … Taiichi Ohno’s categorization of the seven major wastes typically found in mass production: Overproduction: Producing ahead of what’s actually needed by the next process or customer. The worst form of waste because it contributes to the other six.

TIM WOOD (S) is een ezelsbruggetje om de 7 vormen van Waste eenvoudig te onthouden.. Transport: onnodige verplaatsing van iets, zoals een aanvraag voor een vacature die voor goedkeuring langs meerdere verschillende functionarissen moet.; Inventory: voorraad, (werk wat niet af is), zoals ongelezen e-mails of klantcases in behandeling, of een “pool” met ongebruikte leaseauto’s. TRAINING 7 WASTE (7 PEMBOROSAN) Developing a Lean Hospital Management System Lean Enterprise Academy. The lean hospital what is mean Emad Kotb. Managing Lean Hospitals Lean Enterprise Academy. Basic concept of quality final by DR.MUSHTAQ.A.KHOSA Mushtaq …

Verspilling (waste) is alles wat geen waarde toevoegt aan het product of de dienst in de ogen van de klant. Alle processtappen kosten tijd en geld. Lean streeft ernaar binnen een proces alleen processtappen te hebben die waarde toevoegen. In order to become a world-class company it is fundamentally important to eliminate and to avoid all 7 types of waste (muda) in manufacturing and also in service processes. How can we describe “waste”? Any activity or process that adds costs but adds no value (for the customer). There are 7 types of waste identified: 1) Overproduction

Muda (無駄, on'yomi reading) is a Japanese word meaning "futility; uselessness; wastefulness", and is a key concept in lean process thinking, like the Toyota Production System (TPS) as one of the three types of deviation from optimal allocation of resources (the others being mura and muri). Waste reduction is an effective way to increase profitability. 12-2-2012 · This video describes the seven wastes first identified by Taiichi Ohno of Toyota Production System fame. This concept is one of the most important in lean manufacturing. Presented by EMS

up for sale is a used 2 person dome tent made by escort Also available is a broadstone picnic shelter. this is the EZ up instant version. goes up in less than a minute. it is 13x15 feet and can fit 7-10 people. this is used and has seen better days (has a few patches etc), but still works fine and keeps the bugs out. all poles are in excellent shape, Both tent and food shelter for $40 or best Broadstone beaumont cabin tent 13 person manual Kongorong Beaumont 13-person cabin tent features durable water-resistant fabric with fully-taped fly seams. Shock-corded steel side poles provide stability while fibreglass roof poles with sleeves ensure easy assembly. Large windows with zippered storm flaps and mesh roof panels improve ventilation. Removable curtains divide tent into 4 rooms. Cabin tent