A manual hydraulic press is a device used to apply controlled force in various industrial tasks. It operates via hydraulic pressure, enabling precise metal shaping, punching, and embossing.

1.1 Definition and Purpose

A manual hydraulic press is a mechanical device that uses hydraulic pressure to exert force for shaping, punching, or embossing materials. It operates manually, relying on fluid dynamics to amplify force applied by the user. Primarily used in metalworking, fabrication, and plastics, it offers precise control over pressure, making it ideal for tasks requiring accuracy. Its purpose is to deliver consistent and reliable force in industrial and workshop settings, enabling efficient processing of materials with minimal effort compared to traditional methods.

1.2 Importance in Industrial Applications

Manual hydraulic presses are essential in various industries due to their versatility and precision. They are widely used in metalworking for stamping, shaping, and embossing, as well as in plastic molding for forming and shaping materials. Their ability to deliver consistent pressure makes them ideal for small-scale production and workshops. Additionally, they are cost-effective and require minimal setup, making them a preferred choice for industries needing reliable, low-maintenance equipment for specific tasks. Their adaptability ensures they remain a vital tool in modern manufacturing processes.

History and Evolution

The manual hydraulic press evolved from Bramah’s 1795 invention, adapting to industrial needs with cost-effective, precise solutions for metalworking, fabrication, and molding over the years.

2.1 Early Developments in Hydraulic Press Technology

The hydraulic press traces its origins to Joseph Bramah’s 1795 patent, revolutionizing metalworking with controlled force application. Early models relied on manual operation, using fluid pressure to amplify force, enabling precise metal shaping and embossing. By the 19th century, advancements in materials and engineering led to more efficient designs, paving the way for industrial applications in metal fabrication and beyond.

2.2 Transition from Automatic to Manual Operation

The shift from automatic to manual hydraulic presses addressed specific industrial needs for precision and control. Manual operation allowed operators to adjust pressure and speed, enhancing customization in tasks like metal embossing and shaping. This transition also reduced reliance on complex automation, making the technology more accessible for smaller workshops and specialized applications where human oversight was crucial for intricate processes.

Working Principle

A manual hydraulic press operates by converting manual effort into hydraulic pressure, using fluid to generate force for tasks like metal shaping. It offers precise control and efficiency in industrial applications.

3.1 Basic Mechanism of Hydraulic Pressure

A manual hydraulic press uses fluid dynamics to generate force. When the operator applies effort, it pressurizes hydraulic fluid, which then transfers force to the workpiece. This mechanism ensures precise control over pressure distribution, enabling tasks like metal shaping and punching with consistency and accuracy.

3.2 Role of Fluid Dynamics in Operation

Fluid dynamics play a crucial role in the operation of a manual hydraulic press. Hydraulic fluid transmits pressure evenly, converting mechanical effort into controlled force. The fluid’s incompressibility ensures efficient energy transfer, enabling precise operation. Proper fluid flow and pressure distribution are essential for consistent performance, making fluid dynamics fundamental to the press’s functionality and reliability in industrial applications.

Design and Construction

Manual hydraulic presses feature a robust structure with high-strength materials, ensuring durability. Their compact design includes a stable frame and precise control mechanisms for efficient operation.

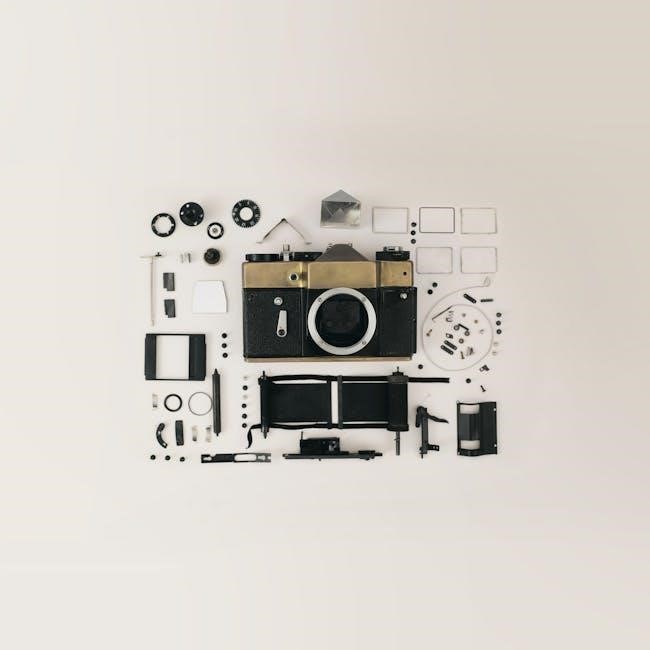

4.1 Key Components of a Manual Hydraulic Press

A manual hydraulic press consists of a hydraulic cylinder and piston for generating force, a manual pump to pressurize fluid, and valves for controlling flow. The steel frame ensures stability, while the worktable holds the material in place. Additional components include pressure gauges for monitoring force and control levers for operation. These elements work together to deliver precise and consistent pressure, making the press versatile for various industrial tasks.

4.2 Materials Used for Durability and Efficiency

Manual hydraulic presses are built with high-strength steel for the frame and stainless steel for hydraulic components, ensuring durability and resistance to corrosion. The hydraulic cylinder and piston are crafted from robust alloys to withstand heavy loads. Seals and gaskets are made from high-grade rubber for leak-proof operation. Additionally, bronze or aluminum may be used for moving parts to reduce friction. These materials ensure the press operates efficiently and maintains performance over time, even in demanding industrial environments.

Types of Manual Hydraulic Press

Manual hydraulic presses are available in single-action, double-action, and customized models, each tailored for specific industrial applications, ensuring versatility and efficiency in metalworking and other tasks.

5.1 Single-Action Press

A single-action manual hydraulic press operates by applying force in one direction only, ideal for stamping, shaping, and embossing tasks. Its simplicity ensures cost-effectiveness and ease of operation, making it suitable for small-scale metal fabrication and plastic molding. The press uses a single piston to generate pressure, offering precise control for delicate operations. Common applications include creating custom parts and repairing equipment. Its compact design and reliability make it a preferred choice for workshops and small industries requiring consistent, low-to-medium pressure outputs.

5.2 Double-Action Press

A double-action manual hydraulic press applies force in both upward and downward directions, enhancing versatility for complex tasks like deep drawing and metal forming. It features two pistons, one for pressure generation and another for ram return, improving efficiency. This press is ideal for industries requiring precise control over dual operations, such as automotive and aerospace. While more complex than single-action models, it offers superior performance for intricate shaping and molding. Regular maintenance is essential to ensure optimal functionality and longevity of the press.

5.3 Customized Models for Specific Tasks

Customized manual hydraulic presses are tailored to meet specific industrial needs, offering enhanced functionality for unique operations. These models are designed in collaboration with clients to address particular challenges, such as vulcanization or high-performance tasks. Structural adaptations, like four-column frames, improve stability and precision. Custom presses often feature advanced controls and specialized tooling, ensuring optimal performance for niche applications. This adaptability makes them invaluable in industries requiring tailored solutions, balancing efficiency and durability for specialized workflows.

Applications in Various Industries

Manual hydraulic presses are essential in metalworking for shaping and punching, in plastic molding for shaping materials, and in various industrial tasks for precise operations.

6.1 Metalworking and Fabrication

Manual hydraulic presses are widely used in metalworking for stamping, punching, and embossing operations. They enable precise shaping of metal components with controlled force, ensuring high accuracy. In fabrication, these presses are essential for cutting, bending, and assembling metal sheets or plates. Their compact design and manual operation make them ideal for workshops and small-scale production. Additionally, they are utilized in metal processing for tasks like riveting and forming, offering versatility and efficiency in various industrial settings.

6.2 Plastic Molding and Shaping

Manual hydraulic presses play a significant role in plastic processing, enabling precise molding and shaping of plastic materials. They are used to create molds, shape plastic sheets, and form custom parts with controlled force. These presses are particularly useful for tasks like thermoforming, where heat and pressure are applied to shape plastics. Their versatility and ability to handle small-scale production make them ideal for workshops and small manufacturing lines, ensuring efficient and accurate plastic fabrication processes.

6.3 Other Industrial Uses

Manual hydraulic presses are versatile tools in various industrial applications beyond metalworking and plastics. They are widely used in vulcanization processes for rubber products, ensuring high-performance bonding. Additionally, these presses are employed in automotive repair shops for tasks like bearing extraction and gear pressing. In construction, they assist in shaping and assembling components. Their compact design and precise control make them ideal for small-scale manufacturing and custom fabrication tasks, offering reliability and efficiency across diverse industrial needs.

Safety Considerations

Operating a manual hydraulic press requires proper training, protective gear, and regular inspections to prevent accidents. Ensure safe practices to avoid fluid leakage and mechanical failures.

7.1 Operational Safety Guidelines

Ensure all operators are properly trained and wear protective gear, including gloves and safety goggles. Regularly inspect hoses, valves, and cylinders for damage or leaks. Maintain a clean workspace to prevent accidents. Follow manufacturer guidelines for pressure limits and operation. Never overload the press beyond its capacity. Use jigs and fixtures to secure workpieces firmly. Implement emergency stop mechanisms and keep the area clear of obstructions. Always refer to the manual for specific safety protocols tailored to your press model.

7.2 Emergency Shutdown Procedures

In case of an emergency, immediately activate the emergency stop button to halt the press. Ensure the hydraulic system is depressurized before attempting any intervention. Secure the workpiece and surrounding area to prevent movement. Evacuate the area if necessary and alert other personnel. Follow the manufacturer’s specific shutdown protocols, as outlined in the manual. Regularly test emergency systems to ensure functionality. Always prioritize operator safety and avoid sudden actions that could exacerbate the situation. Keep emergency contact information readily available.

Maintenance and Repair

Regular maintenance ensures optimal performance of a manual hydraulic press. Check hydraulic fluid levels, inspect seals, and address wear promptly to prevent operational issues.

8.1 Regular Maintenance Tips

Regular maintenance is crucial for optimal performance of a manual hydraulic press. Check hydraulic fluid levels daily, inspect seals for wear, and ensure all connections are secure. Lubricate moving parts periodically to reduce friction and prevent corrosion. Clean the work area and components regularly to avoid contamination. Schedule professional inspections annually to address potential issues early. Proper upkeep extends the lifespan and efficiency of the press, ensuring reliable operation in industrial settings.

8.2 Common Issues and Solutions

Common issues with manual hydraulic presses include hydraulic fluid leakage, slow operation, and worn seals. To address these, inspect connections regularly and tighten loose fittings. Replace damaged seals promptly to prevent fluid loss. For slow operation, check fluid viscosity and ensure the pump is functioning correctly. Clean or replace clogged valves to maintain proper flow. Addressing these issues early prevents downtime and ensures consistent performance in industrial applications.

Troubleshooting Common Problems

Common issues with manual hydraulic presses include fluid leakage and low pressure. Check connections for leaks and inspect the pump and valves to ensure proper operation.

9.1 Hydraulic Fluid Leakage

Hydraulic fluid leakage is a common issue in manual hydraulic presses, often due to worn seals or loose connections. Regular inspection of seals and gaskets is essential to prevent fluid loss, which can lead to reduced pressure and efficiency. Tightening fittings and replacing damaged components can resolve most leaks. Using high-quality hydraulic fluid and maintaining proper system pressure also helps minimize leakage risks. Addressing leaks promptly prevents further damage to the press and ensures safe, reliable operation.

9.2 Insufficient Pressure Output

Insufficient pressure output in a manual hydraulic press can hinder productivity. Causes include low hydraulic fluid levels, incorrect pressure settings, or pump inefficiency. To resolve this, check fluid levels, ensure proper pressure calibration, and inspect the pump for wear. Regular maintenance, such as filter cleaning and seal inspection, can prevent pressure drops. Addressing these issues promptly ensures optimal performance and extends the press’s lifespan.

Comparison with Automatic Hydraulic Press

Manual hydraulic presses offer cost-effectiveness and portability, ideal for small-scale tasks. Automatic presses, however, excel in high-speed production and integration with smart technology for advanced manufacturing needs.

10.1 Advantages of Manual Operation

Manual hydraulic presses offer cost-effectiveness, portability, and simplicity, making them ideal for small-scale operations. They require minimal setup and are easy to operate, reducing reliance on advanced training. Customization options cater to specific tasks, ensuring precision in metalworking, embossing, and punching. Their compact design suits workshops with limited space, while lower energy consumption enhances sustainability. Additionally, manual presses are less prone to mechanical failures compared to automatic models, providing reliable performance for consistent workflows.

10.2 Limitations Compared to Automatic Press

Manual hydraulic presses are less efficient for large-scale production due to their reliance on human effort, making them time-consuming for high-volume tasks. They also lack the precision and speed of automatic presses, which can handle complex operations with minimal supervision. Additionally, manual presses often require more skill and physical effort, limiting their suitability for continuous workflows. Their smaller capacity restricts them to lighter-duty applications, making automatic presses more advantageous for heavy industrial needs and high-speed manufacturing processes.

Market Overview

Key manufacturers like Hidrogarne offer customized manual hydraulic presses, catering to specific industrial needs. The market sees growth in tailored solutions and innovative, eco-friendly models, meeting diverse demands.

11.1 Key Manufacturers and Suppliers

Leading manufacturers like Hidrogarne specialize in manual hydraulic presses, offering customized solutions for industrial needs. Their presses, such as the MV-1000 E, are designed for high-performance tasks like vulcanization. Other suppliers focus on durability and efficiency, providing presses for metalworking and fabrication. These manufacturers often cater to specific industries, ensuring their products meet diverse operational requirements. Their innovations and commitment to quality make them prominent players in the global market for manual hydraulic presses.

11.2 Industry Trends and Innovations

The manual hydraulic press industry is evolving with advancements in customization and smart technology. Manufacturers like Hidrogarne are adapting presses to meet specific client needs, such as the RM-500E model for stamping and embossing. Integration with smart systems enhances operational efficiency and monitoring. Eco-friendly designs are gaining traction, focusing on energy efficiency and reduced waste. These innovations ensure manual hydraulic presses remain relevant in modern industrial settings, addressing both performance and environmental concerns effectively.

Case Studies and Real-World Examples

Manual hydraulic presses are widely used in workshops for metalworking and customization. Hidrogarne’s customized MV-1000 E model exemplifies successful implementation in high-performance vulcanization tasks, showcasing practical industrial applications effectively.

12.1 Successful Implementation in Workshops

Manual hydraulic presses, like Hidrogarne’s MV-1000 E, have been successfully integrated into workshops for tasks requiring precision and customization. These presses excel in metalworking, enabling efficient shaping and embossing. Their durability and adaptability make them ideal for small-scale production and specialized fabrication. Workshops leveraging these presses report increased productivity and consistency in output, particularly in vulcanization processes. This demonstrates their practical value in industrial settings, offering a reliable solution for diverse operational needs while maintaining cost-effectiveness and operational simplicity.

12.2 Use in Educational and Training Settings

Manual hydraulic presses are increasingly used in educational institutions for teaching fluid dynamics and mechanical principles. They provide hands-on experience for students, allowing them to understand hydraulic systems and their applications. Technical schools and universities incorporate these presses in lab settings to demonstrate pressure transmission and mechanical advantage. Their simplicity and safety features make them ideal for training future engineers and technicians, ensuring practical knowledge transfer in a controlled environment.

Environmental Impact

Manual hydraulic presses often feature reduced energy consumption and recyclable materials, contributing to eco-friendly operations and sustainable industrial practices.

13.1 Energy Efficiency Considerations

Manual hydraulic presses are designed to optimize energy use, reducing power consumption during operation. Their manual mechanism minimizes reliance on electricity, making them eco-friendly. Additionally, these presses often incorporate recyclable materials, further enhancing their environmental sustainability. This focus on energy efficiency aligns with modern industrial practices aimed at reducing carbon footprints. By leveraging hydraulic pressure without excessive power input, manual presses provide a cost-effective and environmentally responsible solution for various industrial tasks.

13.2 Waste Management and Recycling

Manual hydraulic presses often incorporate recyclable materials, reducing environmental impact. Proper disposal of hydraulic fluids and filters is crucial to prevent contamination. Regular maintenance ensures longevity, minimizing waste. Manufacturers like Hidrogarne emphasize eco-friendly designs, promoting recycling of metal components. Users are encouraged to follow local regulations for responsible disposal. Recycling programs for press parts further support sustainability. By prioritizing waste management, manual hydraulic presses contribute to a greener industrial landscape, aligning with global efforts to reduce waste and promote recycling in manufacturing sectors.

Future Trends and Innovations

Manual hydraulic presses are evolving with smart technology integration and eco-friendly designs. Innovations focus on energy efficiency, customization, and advanced materials for improved performance and sustainability in industrial applications.

14.1 Integration with Smart Technology

The integration of smart technology into manual hydraulic presses enhances operational efficiency and precision. IoT connectivity allows real-time monitoring of press performance, enabling predictive maintenance and reducing downtime. Advanced sensors detect anomalies, ensuring safer operations and optimizing energy use. AI-driven analytics provide insights for process improvement, while automation streamlines tasks, reducing human error. This fusion of traditional mechanics with modern tech creates a smarter, more adaptable tool for industries, aligning with Industry 4.0 goals.

14.2 Development of Eco-Friendly Models

The development of eco-friendly manual hydraulic presses focuses on reducing environmental impact while maintaining performance. Manufacturers are adopting sustainable materials and energy-efficient designs to minimize carbon footprints. Biodegradable hydraulic fluids and recyclable components are being integrated to align with global environmental standards. These models aim to reduce waste and emissions, promoting greener manufacturing practices without compromising functionality. This shift reflects industry efforts to balance productivity with ecological responsibility, ensuring manual hydraulic presses remain relevant in an increasingly sustainability-focused world.

Manual hydraulic presses remain essential tools in various industries, offering precision and reliability. Their versatility and adaptability ensure continued relevance in evolving industrial landscapes and future innovations.

15.1 Summary of Key Points

A manual hydraulic press is a versatile tool for applying controlled force in industrial tasks, offering precision and reliability. Its applications span metalworking, plastic molding, and custom tasks, with models like single-action, double-action, and specialized designs. Safety and maintenance are crucial for optimal operation, while troubleshooting common issues ensures longevity. Compared to automatic presses, manual models provide cost-effective solutions with lower complexity. Their adaptability and efficiency make them indispensable in workshops and educational settings, highlighting their enduring value in modern industries.

15.2 Final Thoughts on the Importance of Manual Hydraulic Press

The manual hydraulic press remains a cornerstone in industrial operations, offering unmatched versatility and precision. Its ability to handle metalworking, plastic molding, and custom tasks underscores its essential role in modern manufacturing. With models tailored for specific needs, it adapts seamlessly to various industries, ensuring efficiency and reliability. Its cost-effectiveness and ease of operation make it a preferred choice for workshops and educational settings. As industries evolve, the manual hydraulic press continues to demonstrate its enduring value, proving it is a timeless tool for achieving high-quality results.